Applicon builds pneumatic conveying systems for rail unloading, in-plant transports, hopper loading, and batch ingredient handling.

Vacuum conveying works well for relatively low rates, say from a few pounds per hour up to 20,000 lb/hr, and over relatively short distance. The longer the convey distance, the less energy efficient, and the greater the attrition to fragile products. Vacuum conveying can also be a very cost effective way of batching multiple ingredients, in a compact space. Movement by vacuum reduces risk when handling combustible mataerial.

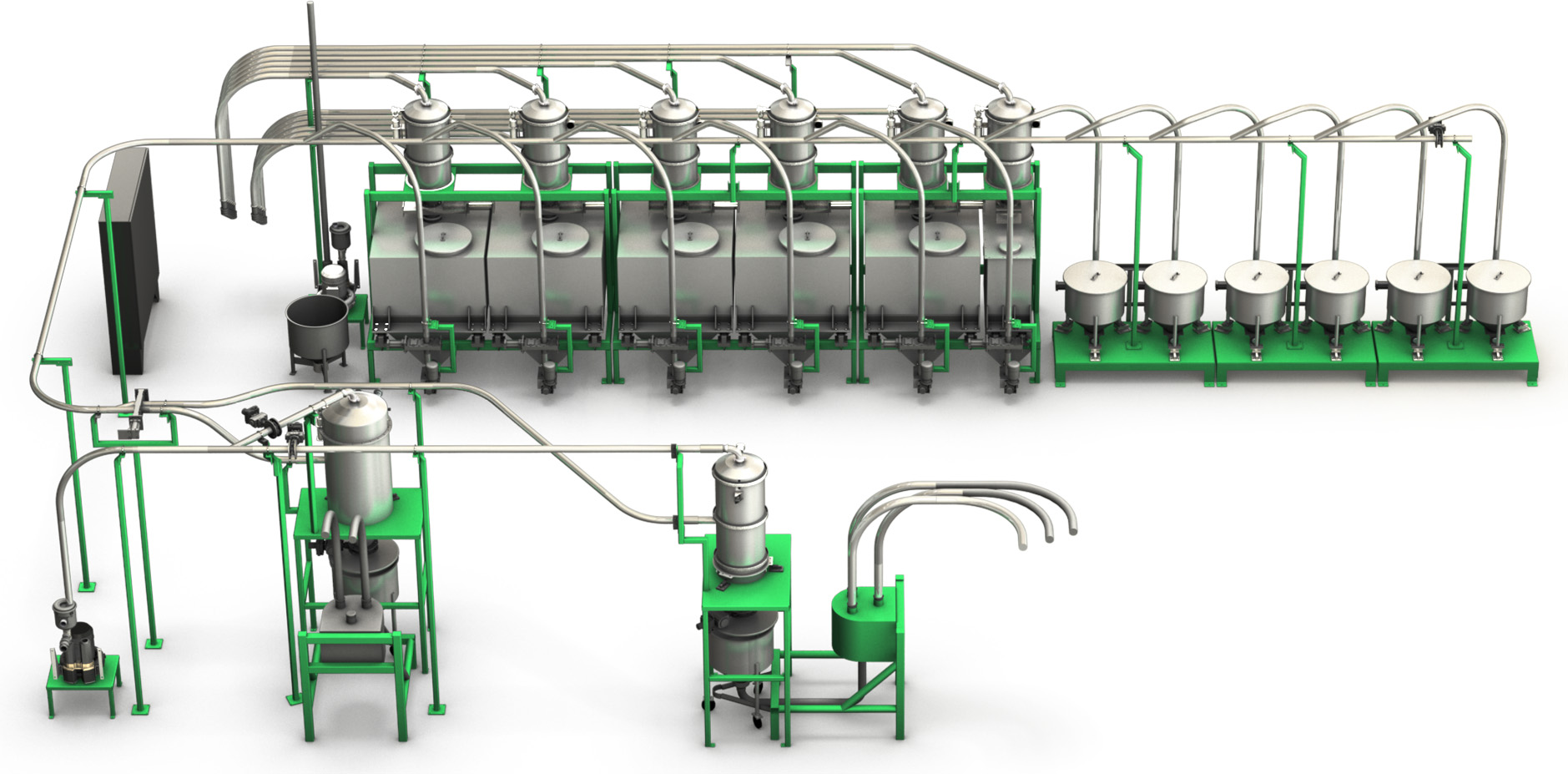

Applicon builds pneumatic conveying systems for rail unloading, in-plant transports, hopper loading, and batch ingredient handling.

Vacuum conveying works well for relatively low rates, say from a few pounds per hour up to 20,000 lb/hr, and over relatively short distance. The longer the convey distance, the less energy efficient, and the greater the attrition to fragile products. Vacuum conveying can also be a very cost effective way of batching multiple ingredients, in a compact space. Movement by vacuum reduces risk when handling combustible mataerial.

Vacuum Loading

We offer standard vacuum loading receivers in 17", 24" and 30" diameters, in mild and stainless construction. Capacities range from a few hundred to 10,000 lb/hr. of granular or powder products. These are available in quick clamp modular, or flange & bolted design, and can be provided with any style of discharge valve.

Vacuum loaders work well for almost any flowable dry bulk material. They are inexpensive, reasonably efficient, and are "path flexible". They don't take up the floor space of a screw conveyor or flex screw. They don't require the straight path of mechanical conveyors, and so can move product easily around process equipment or into production cells or rooms.

Vacuum conveying can also be a very cost effective way of batching multiple ingredients, in a compact space. Movement by vacuum reduces risk when handling combustible material.

Pressure Dilute Conveying

Our dilute pressure transport systems utilize receivers from 24" to 72" diameter, in mild or stainless construction, and have capacities from 2 to 30 tph.

Pressure Dense Conveying

We offer dense phase systems where the convey distance is long, where high rate is required, or where a low velocity is mandated to avoid abrasive wear or to avoid damage to the product being conveyed.

Transport vessels range from 12" to 72" diameter, and the motive air supply can be from 20 to 50 psig.

Dense phase pressure systems utilize a transporter vessel to fluidize and blow air permeable materials, including silica sand, cement, refractory materials, etc. Less permeable products may require air (energy) injection into the convey line in addition to the energy source at the transporter.

Long distance dense phase is also useful for fragile products such as granular sugars (sucrose, dextrose), polymer pellets that may "skin" at high velocity, nuts and foodstuffs.

Dense phase conveyance is not suitable for some types of products, and the choice of dense phase depends on material, convey rate & distance, and abrasiveness. Generally dense phase is not recommended if the system must be used for several products with dissimilar particle distributions or densities.

Pull/Push Conveying

For rail unloading, re-conveying from silo to process, and for some long distance applications, combination systems (or Pull/Push ) provide the best performance.

In such systems, product is vacuumed to a transporter, which is subsequently pressurized to convey the product to destination. Single or dual vessel systems are available, and capacity can exceed 100 tph. The vacuum loading cycle can be accomplished by induced vacuum (eductor) or directly by vacuum blower.

Vacuum Filter Receivers (VFR) VFRs can be designed for side or top access (bag inspection and replacement), and for vacuum up to 17" Hg (very high vacuum). Most systems operate at 4 to 8" Hg vacuum, but dense phase vacuum transport operates at 8 to 17" Hg for at least part of each cycle, with a corresponding reduction in conveying velocity.